Tier 1 Component Supplier Increases Throughput and Returns to On-Time

Overview

After years of cost cutting and loss of experienced “Tribal” manufacturing knowledge, a CBS aerospace client was not able to support increasing customer demand. Though they continued to make promises to return to on-time delivery, they continued to run 9 months delinquent to customer demand. Both the client and the customer were very frustrated with each other. The client was receiving significant oversight but with limited actionable support. When CBS engaged with the client, there was no clear improvement plan in place. Based on our prompt assessment of the situation, CBS developed and implemented an improvement plan that brought the client back to on-time and full condition.

The Challenge

The increasing pressure of a disgruntled customer coupled with years of cost-cutting to make budgets had left CBS’s client with a shortage of experienced operational knowledge. The client was struggling with what actions to take to solve the delinquency problem. To create capacity in their shop, the client began to outsource components with the intended impact of increasing throughput. Unfortunately, this approach was unsuccessful as the suppliers chosen were already at or near capacity and simply took the orders and delivered product when they could—usually weeks late. The sourcing strategy also put severe internal pressure on leadership due to increased costs, thus eroding margins. Finally, the relationship between operators and the management was strained with contract negotiations looming in the very near future.

CBS was challenged with coming into this difficult situation and quickly developing and implementing a meaningful improvement plan.

The Approach

CBS conducted an “alignment session” with existing leadership to immediately understand the challenges and to formulate an action and resource plan to address the issues. With a focus on significantly increasing throughput, CBS embedded a team of process and industry experts to assess and implement required improvements.

After a quick (one week) value stream assessment, the client and CBS team began to develop a new equipment layout that would enable single-piece flow. The incorporation of various lean tools like 2P cell design, standard work and operator balancing allowed the creation of a new manufacturing process. The new production line established standard WIP, balancing both internal and external operations as well as required output. The transformation required 55 major machine moves and 26 scheduling and planning changes over a 24-hour operation.

Just like in every transformation, the easy part was designing the layout and flow and the physically moving the equipment. The true challenge was teaching and coaching every level of employee to the new manufacturing process. CBS leveraged its years of change management skills and its core belief to work alongside the client—a roll up your sleeves and get in the fox hole with you mentality. CBS provided much needed project management support to ensure the equipment and changes in flow were implemented. The key to the transformation was for CBS to embed an operations expert to coach and lead the 21 operators and supervisors/managers. As part of the sustainment activities, CBS deployed a customized version of its proprietary Visual Management and Control System (VMCS). CBS used this system to teach standard work adherence, abnormality management and root cause problem-solving. CBS continued to lead, coach and train the team for approximately 90 days while everyone became conditioned to the new way of operation and major actions/issues were completed.

The critical link to implementing change was to embed a CBS team member to oversee transformation, train the team on new manufacturing processes and secure sustainment.

Statistical Results

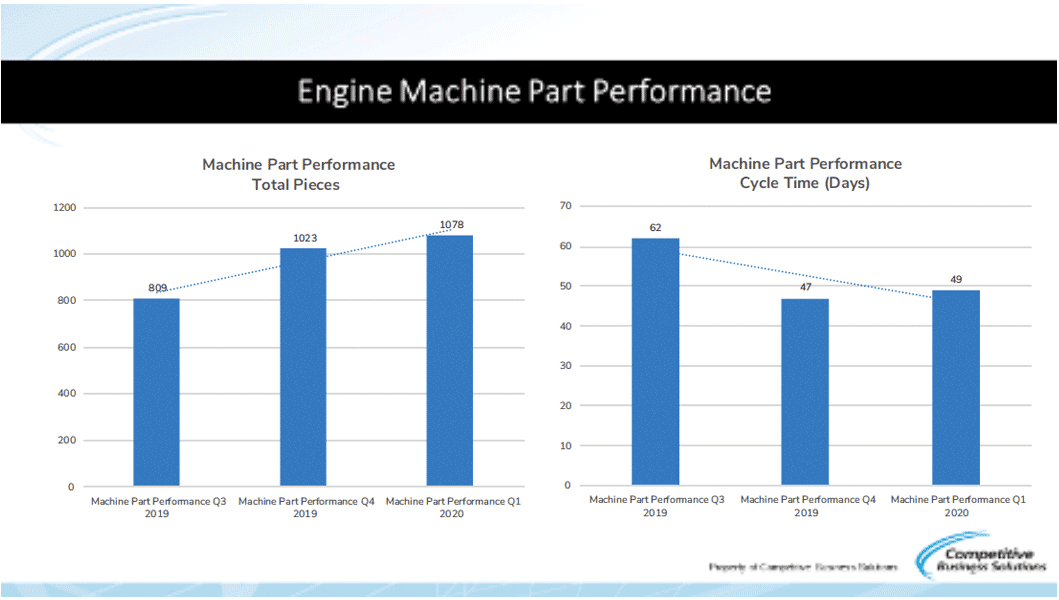

A near immediate throughput improvement of 33% allowed the client to begin getting back on schedule, thus reducing their internal team and the need for oversight. The overall result was a much-improved working environment. Tangible benefits include $1.0M cash due to increased output and savings of $900K in the cost of poor quality.

Conclusion

While the traditional approach towards major change may be to move the equipment and “turn it over to operations” to figure it out, this does not typically yield the kinds of results companies require. The key to this particular transformation is the client provided the required resources to coach, train and sustain the changes implemented. Follow-through, execution and sustainment are the usual challenges that follow any major change, but in this case, the client provided an ongoing resource (CBS) to support the follow-up and sustainability of the improvements. Blending knowledge transfer with execution is a key competency and differentiator for the CBS team.

About Competitive Business Solutions

Competitive Business Solutions consultants are masters of world-class operating and lean sigma principles. Creative problem-solvers throughout the improvement process — from initial discovery and strategic solution development to implementation and knowledge transfer — CBS consultants take pride in their client relationships, working side-by-side with every member of onsite teams to identify performance issues quickly and effectively, with significant and sustainable business improvement as a result.

Latest Insights

Sign up to receive our latest insights!

"*" indicates required fields