Overview

CBS worked with a Tier 2 client to help struggling suppliers and bring them “Return to Green”. One of CBS’s clients was struggling to meet customers’ expectations, which often leads to customer oversight and additional statusing requirements. CBS partnered with their client to understand the root cause of the delinquent performance and went to work solving the two main issues, both tied to supplier performance.

The Challenge

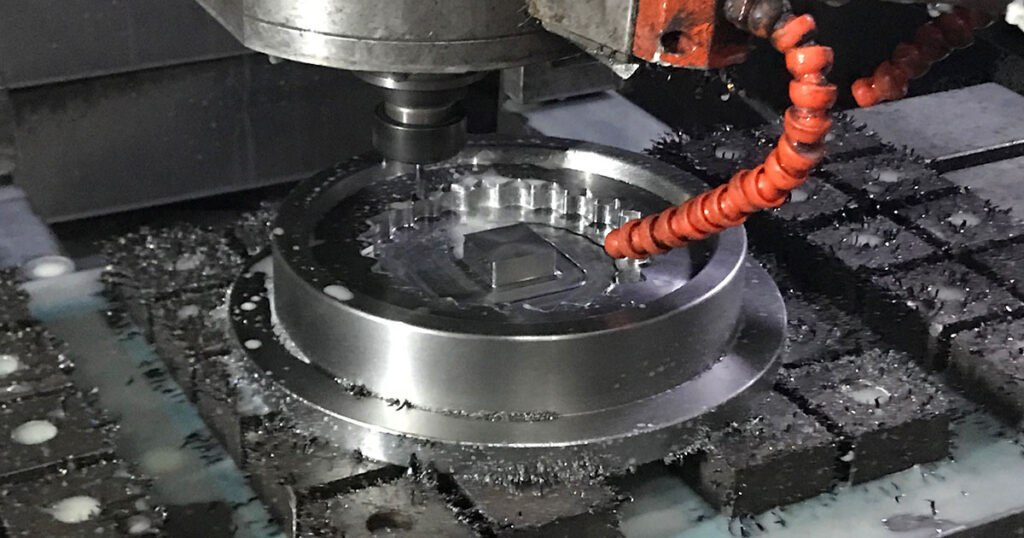

With today’s supply chain challenges of a diminishing work force and down-stream material shortages, it is just too easy to just blame the supply chain and “do the best you can.” In this instance, CBS’s client decided to help their supply base by engaging CBS to use their expertise to improve supplier performance. The struggling suppliers were dealing with many of the traditional operational issues from problems with quality and machine capacity, to labor shortages and no clear understanding of customer’s priorities. The goal of the engagement was not to come in and simply provide oversite and status reports but to quickly get parts flowing to break the Tier 2’s customer delivery issues and to implement processes to prevent the Tier 3 from quickly slipping back into a delinquent position.

“I was very skeptical about having outside help. CBS came in and went to work solving issues that we had been dealing with for years.”

– Plant Manager, Tier 3 Supplier

CBS completed a quick root cause analysis on what was causing the Tier 2 client to miss delivery commitments and determined it was due to part shortages from two suppliers. CBS and the Tier 2 worked together to develop an approach that was mutually beneficial for both the Tier 2 and Tier 3 suppliers. CBS then deployed resources to each of the Tier 3 suppliers to quickly diagnose, understand and develop an improvement plan to correct the delivery issues. A two-tiered approach was used to address performance issues, first was a triage effort to immediately impact the delinquency and second create a systemic transformational improvement effort to bring the Tier 3 “Return to Green.”

CBS worked alongside the Tier 3 management and operators alike establishing clear expectations with the Tier 2 and to take actions that quickly increased flow of critical parts. CBS was able to provide an unbiased voice helping both the supplier and customer to see the effects each other’s actions had on the other. This basic communication helped cut through inherent issues that had existed for some time.

CBS also worked to help the Tier 3 implement immediate impact tools to break constraints such as establishing escalation policies, managing the WIP to keep downstream processes fed, implemented TPM on a critical piece of equipment, offloaded work both from constrained machines and suppliers, and finally staffing critical machines throughout breaks and lunches. While these may seem obvious, they are not so obvious when in the middle of the battle. CBS provided the extra resources the Tier 3 needed to see and implement these tools. While this provided quick results for the Tier 2, more importantly it allowed CBS and the Tier 3 to start implementing some more permanent solutions.

CBS established creditability with the Tier 3 supplier and created desire to shift resources from short term actions to long-term solutions to create a “Return to Green” permanent shift to maintain customer on-time delivery requirements with less manual intervention. In this case, CBS helped identify and implement:

- A scheduling process to manage known demands and short lead-time drop ins

- Visual FIFO lanes

- Pull system tied to Tier 2 requirements

- Tiered Visual Management System to drive abnormality management

- Root Cause and Counter Measure mindset

- Capacity enablers

- Flow cells where feasible and virtual cells where direct linkage was not possible

- SMED

- Lot size adjustment

- TPM

- Off-Loading (internal and external)

- I mplemented quality process to improve

First Pass yield (FPY)

“CBS did an outstanding job of providing a neutral view on issues we were causing our supplier. They helped us solve those issues and improve both organizations performance.”

– Senior Supplier Development Manager, Tier 2 CBS Client

CBS also trained and coached the Tier 3 team to understand and transitioned ownership of improvement initiatives from CBS to area leadership.

Statistical Results

By applying the triage and Return to Green methodology CBS was able to help the constrained Tier 3 suppliers attain the following results:

Triage Phase

- On-Time-Delivery to customer need from 70% to 85%

- Throughput increases from 90 to 180 units per month

“Return to Green”

- On-Time Delivery to customer need from 85% to 96%

- Throughput increases from 180 to 247 units per month

- Improved first pass yield quality issues by 50%

Conclusion

An initiative-taking Tier 2 CBS client decided not to accept the status quo and to instead, help their Tier 3 suppliers improve by providing operational expertise to “Return to Green.” The work of all the organizations will have lasting results to all parties as they continue to strengthen their partnership for years to come. CBS worked with a Tier 2 client to help struggling suppliers and bring them “Return to Green”.