Overview

A CBS client manufactures machined assemblies in the aerospace and defense industry. The receiving function was creating a significant bottleneck in the operation and causing delays at multiple points in the production process. The solution required input from several functions and needed to overcome multiple process challenges to be effective and sustainable. CBS recommended a Kaizen event for the Receiving Inspection process to achieve quick results and develop standardized processes.

The Challenge

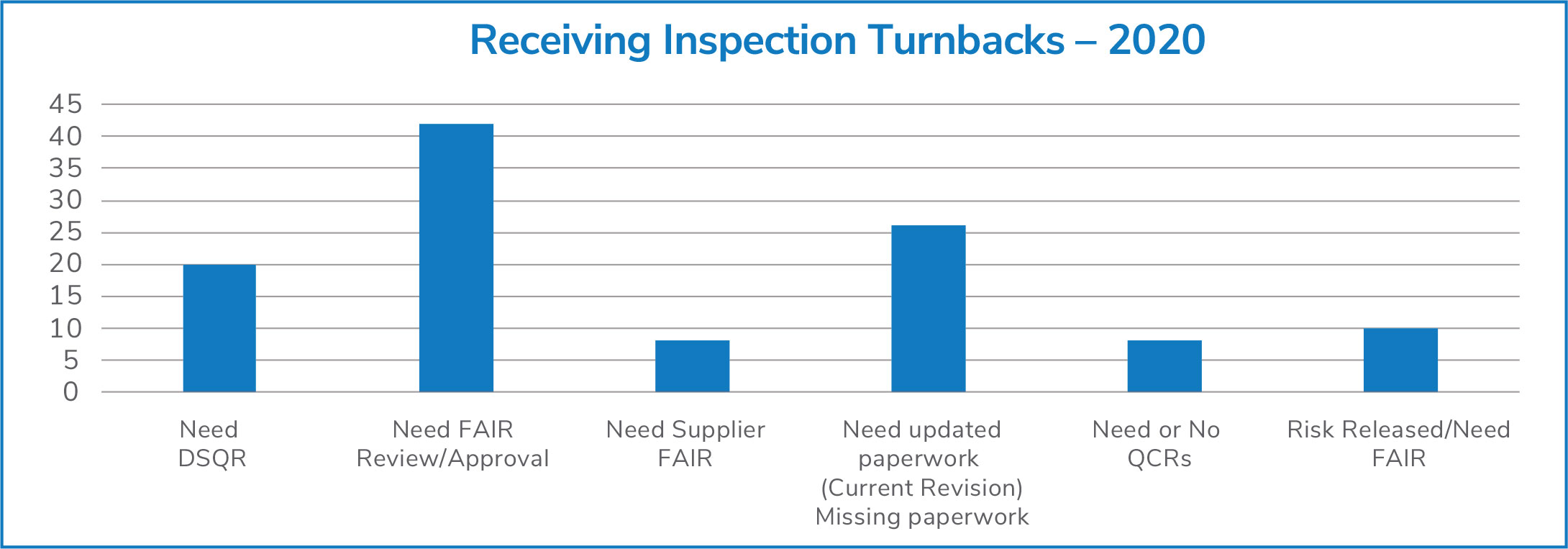

A Receiving Inspection backlog of 307 orders, 80% of those being more than 30 days aged, was impacting the client every day. Some jobs were more than a year old, and the reasons for stalled jobs were difficult to visualize due to cluttered storage. Each month resulted in over 100 jobs stuck due to process or paperwork discrepancies. At the time of the event, 26 orders were lacking a simple update to paperwork from a supplier.

As with most manufacturing organizations, resource constraints made it difficult to overcome the volume of waste that was being generated by the lack of process. Daily impacts to Purchasing, Planning, Receiving and Quality were creating frustration and inefficiencies. Communications were plentiful, but rarely effective, and the team was not able to navigate out of the forest; they were consumed by the daily firefight.

“It was amazing to see how fragmented the existing process is and it requires a lot of extra communication.”

– H.L., Quality Manager

A CBS resource was filling a critical Quality role for the client as new personnel were being hired and onboarded. During daily leadership meetings, it became clear that a week-long Kaizen event could benefit the team and help organize the area with visual controls and standard work.

The Approach

To understand the problem and ensure that the team was acting on sound evidence and not feelings, data was gathered from the impacted functions. Existing holds, reasons for stalls, typical process interruptions, and the current state of Receiving Inspection inventory were all captured to build Pareto diagrams. These charts were used to scope the event; it was critical for the Receiving Inspection team to support the activity and keep up with daily shipment processing to avoid further delays.

The data provided significant insight into the day-to-day Inspection challenges:

- 30 minutes – Average time spent looking for an incoming job

- 1.5 hours/day – Time wasted looking for parts

- 30 times/week – Incoming jobs missing paperwork

- 70 times/week – Interruptions to Inspection team for status updates

- 15 times/week – Parts are lost; cannot be located

- 100+ times/week – Parts are turned back for various reasons

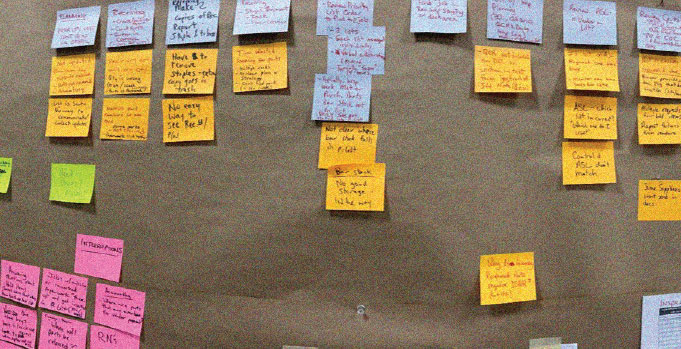

The team started the week by obtaining Voice of the Customer/Voice of the Supplier data. Subject-matter experts in impacted functions provided insight to customer and organizational impact. This data was used along with Gemba Walk observations to build a process map with Kaizen bursts indicating opportunities for quick action. It rapidly became clear that more-efficient communication methods could yield significant reduction in waste.

With the upstream and downstream impacts identified, the focus turned to the staging and queuing area in Receiving Inspection. Racks were covered with stacked, double-deep containers and boxes, making it almost impossible to find needed inventory. The team created a new visual standard using one critical identifier: the Receiver Number. Standard Work was created to provide visibility to all items on a rack within seconds.

Tracking charts populated a new Tier 2 Metric Board where the leadership team could assess resource needs and provide support each morning to achieve business goals. A Daily Priority List showed all parties what was needed/completed—thus, eliminating interruptions, email and phone calls. A “Coming Soon” list kept personnel aware of critical shipments. Interruptions and delays were tracked on a live Pareto to drive action and problem-solving efforts.

“This will make it so much easier for my team to update the customer. We can simply look at the board and not have to interrupt the Inspectors.”

– D.R., Quality Manager

Statistical Results

By the end of the Kaizen week, the team had achieved or was on target to achieve the following improvements:

- Time to locate a job – 2 minutes (93% reduction)

- Processing time for Outside Processing jobs – 48 hours (71% reduction)

- Inspector interruptions – 2–3/day (78% reduction)

- Turn time for holds/First Article review – 5 days (67% reduction)

Conclusion

Most Kaizen activities are simply structured activity with focused resources to attack a well-scoped problem—this event was no different. The formula is simple and, in this case, started with the foundational 5S principles: Sort, Set In Order, Sweep, Standardize and Sustain. By organizing the inventory/information, and creating visual standards, anyone would now be able to quickly find what they need without interrupting others. Metrics reviewed during daily Gemba Walks provided guidance to the support needed from the Leadership Team. With a significant reduction in internal frustration and increase in efficiency throughout the area, client and customer saw significant benefits and could focus on the next improvement effort!