CLIENT INDUSTRY: Tier 2 Aerospace and Defense Company

SOLUTION: Operational Excellence, Supply Chain

A Tier 2 supplier of wings with revenues of more than $3 billion, contracted with CBS. Several process issues seriously threatened the client’s ability to meet customer demands for delivery, cost, and quality. CBS helped the client achieve significant reductions in unit labor hours, defect rates, and product rework; a return to on-time deliveries; and resulting in achieving their fiscal revenue targets.

Business Challenge

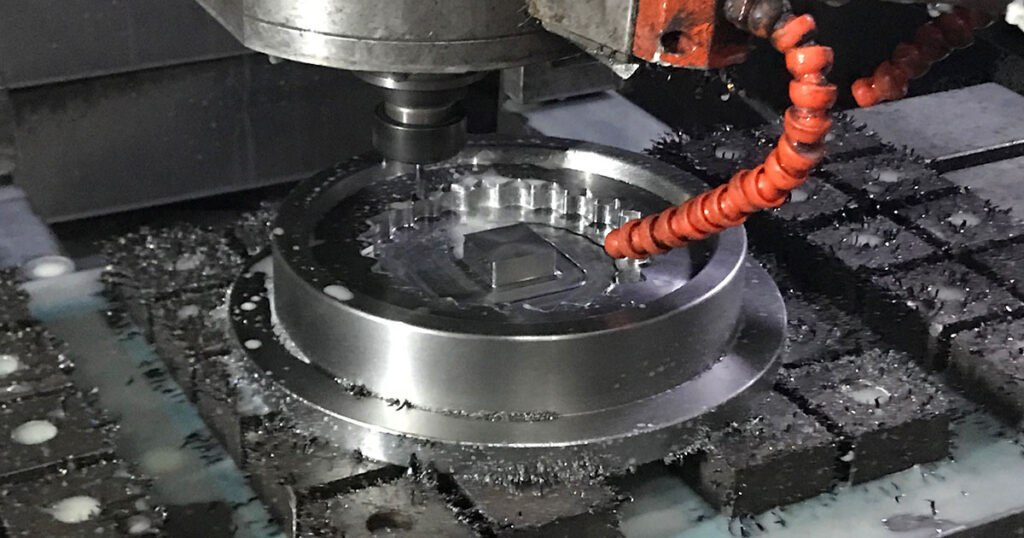

A Tier 2 supplier of wings, with revenues of more than $3 billion, contracted with Competitive Business Solutions (CBS) in 2017. The client took over production from a Tier 1 supplier that was reducing its manufacturing footprint. The plant had seen significant turnover in both its leadership and labor along with prolonged inattention to capital improvements and routine maintenance. These circumstances seriously threatened the client’s ability to meet customer demands for delivery, cost, and quality.

Solution

Results

Competitive Business Solutions helped the client save 6 million dollars annually. Program on-time delivery was increased from 77% to 100%. CBS reduced the client’s labor hours by 14%, a total of 1,900 hours, and reduced quality defects by 43% CBS also improved CNC equipment uptime 30% and implemented program basic skills training. At the time of departure, CBS had trained 42% of the workforce.