CLIENT INDUSTRY: Aerospace and Defense Company

SOLUTION: Operational Excellence

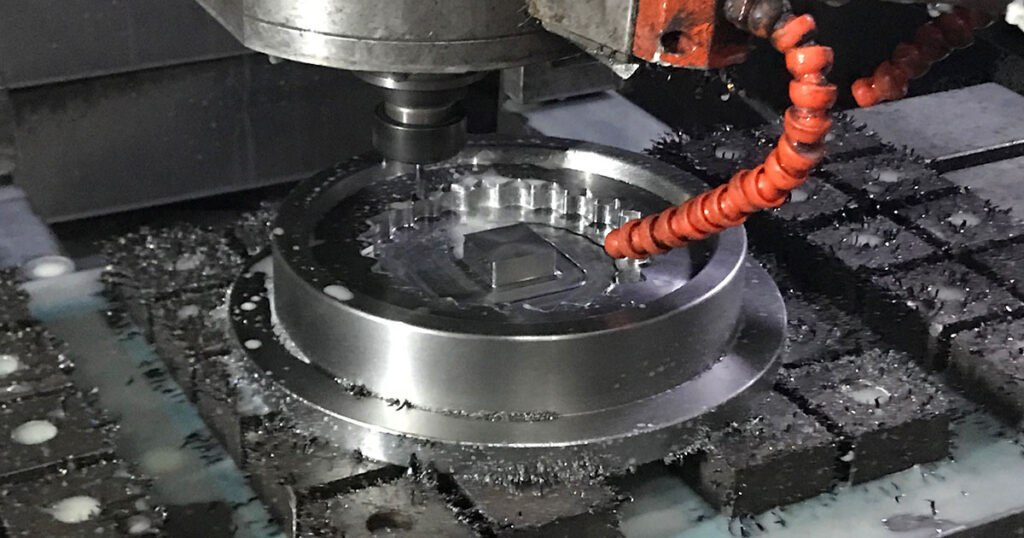

The client is a designer, manufacturer, and integrator of very high-technology military product. The company lacked the capacity to meet its customers’ demands, resulting in extreme customer dissatisfaction that had progressed to threats of drastic measures, Because of contractual penalties, the company stood to lose money and orders if it could not meet promised delivery dates.

Business Challenge

Solution

- CBS thoroughly studied the client’s production facilities and capabilities and recommended the most appropriate production system based on the volume and variation of the products.

- The consultants determined the theoretical lead time of each product line and used that to establish strategic objectives for each area.

- Process improvement personnel in each area of the client company were engaged fully to ensure that changes to the production system would be sustainable.

- A team of CBS consultants and the client company’s assembly personnel:

- Developed capacity tools for critical product lines and incorporated these tools into sales and operations processes.

- Identified and eliminated non-value-added activities.

- Implemented a takt-based system in a low-volume, high-mix environment that divided tasks into day buckets.

- Trained operators and leadership in the new system.

Results

- Doubled shop capacity in four months.

- Reduced product lead time from 50 days to 13 days.

- Increased productivity by 40%, resulting in a return of approximately $10 million over a two-year period.

- The production line has sustained these improvements with little outside intervention.