Is the Quality Revolution Dead?

May 21, 2020 | by Todd Hanlin

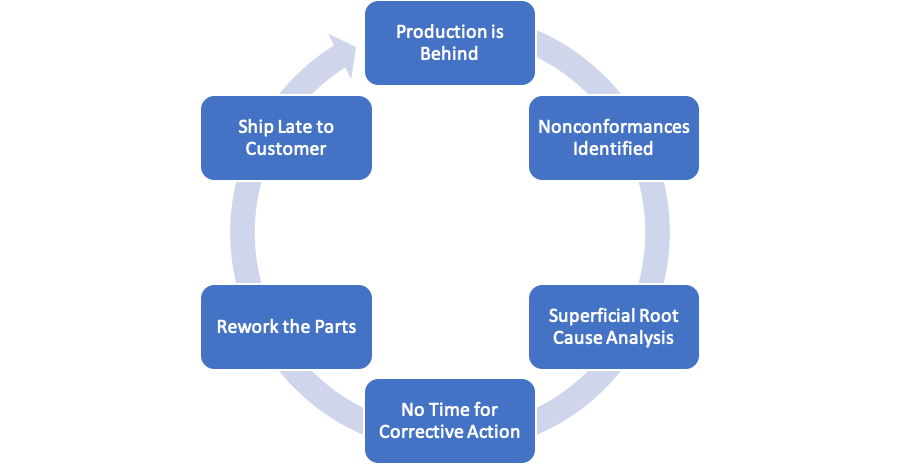

Total Quality Management has been a topic of discussion for more than 70 years. In my experience, it frequently boils down to one question: Do you want Production or Quality? Which one is more important? The answer normally depends on who you ask. The age-old adage is typically rehashed as a result of this cycle:

Sound familiar? Dr. Deming expounded on the answers to this dilemma over 60 years ago, yet I am always surprised by how many facilities still accept this faulty mode of operation.

W. Edwards Deming was considered by many to be the master of continual improvement in quality as well as other aspects of operations. In his 1982 publication, Out of the Crisis, his 14 Points for Management included several simple philosophies:

- Break down barriers between departments;

- Cease dependence on inspection to achieve quality;

- Empower everybody in the company to work toward accomplishing the transformation.

My experience, along with input from colleagues in the manufacturing industry, shows that these principles are still commonly missing in many companies. Why is this the case?

I would submit that Leadership Commitment (or lack thereof) coupled with a gradual decay of processes are the most prevalent causes for ineffective modes of operation. Tier 1 customers drive cost reductions through the supply chain as an expectation. Leadership responds with cuts, not improvements. Processes are left unchecked, and problems hastily patched over with non-sustainable solutions because “we don’t have time for that.” Ultimately, a firefight begins because the vision was not kept in front of the team: “We must all work together and spend a portion of our time fixing our biggest problems.”

| Q: Why do we inspect these parts 100%? A: It was a Corrective Action response in 2006. |

As time marches on, we substitute problem-solving with inspection steps and audits that compound as a result of ineffective corrective action. Upstream processes become dependent on downstream gates to catch defects. Rework and scrap become routine until the cost is large enough to garner leadership’s attention. At that point, fault and blame enter the equation, so silos begin to form. The culture has digressed and turning the ship has now become a much more daunting task.

This unintentional “process” quickly develops into a norm based in firefighting and non-value- added loops. At this point, recovery for most teams will be dependent on outside resources. A fresh set of eyes can quickly discern the largest sources of pain and develop the needed improvement plan. While this comes at an additional immediate cost, it pales in comparison to the alternative of not utilizing the appropriate help. Seasoned professionals give up and leave. Job satisfaction plummets. Frustration increases and dysfunction prevails. Everyone feels the result, but internally, nobody has the answer. So, what can we do?

Deming recognized the inter-related pieces of Transformational Management. He understood that the shift in Quality Culture begins with teaching the managers:

- Break down the walls. Focus on both internal and external Customer-Supplier relationships.

- Equip the team. Cast the vision to every employee; teach them to be successful; empower them to generate change.

- Fix the process. Identify prime targets; implement sustainable solutions.

- Expect the change. Leadership must be responsible for driving the change by supporting the team.

By setting expectations and providing the necessary support framework, the goal becomes achievable and Quality Management morphs to Business Management.

Is the Quality Revolution dead? I don’t think so, but it is easy for us to get off track over time. Sometimes, we just can’t get out of our own way. Fresh eyes can often help us see the forest through the trees. An extra hand can help us over the next hurdle. Often, this kind of help is the catalyst we need to begin the culture shift. Over time, the momentum builds again, the team is revitalized, and quality becomes an integral part of every employee’s day, providing the foundation on which we run our businesses. Suddenly, it is not a matter of Production OR Quality; now we get both!

Blog Posts

Two Quick Key Indicators for Assessing the Health of a Company Before Acquisition

Driving Strategic Change Through Culture

Operational Assessment Before You Sell

How to Use Problem-Solving Strategies to Reduce Workplace Attrition

Engaging Employees to Drive Transformation

SIOP: The Heartbeat of Success

“We Don’t Make Cars Here” – Continuous Improvement Opportunities

Surviving the Tsunami of Labor Shortages

Part 1/2: Five Action Tips to Slay the Data Monster in 2023

Share Available Improvement Opportunities With Potential Buyers

Join our community.

Sign up now to receive future news.