Applying Lean Construction Methodology to Ship Repair Reduces Delays and Overages

Overview

An executive, having previous success with Competitive Business Solutions (CBS), once again engaged our team to provide support for a repair shipyard. Before our arrival, a corporate team had conducted a large Root Cause Corrective Action (RCCA) event in response to the site’s poor performance of contracted repairs. This was evidenced by significant cost overruns and frustrated customers. Fixed-price contracts were commonly blamed for the site’s issues.

CBS was asked to help the team understand and improve the situation of the repairs not progressing (progressing issues) at the pace anticipated or required. It was quickly apparent that poor alignment (departmental silos’ over-the-wall mentality) between the master schedule, project management and trade’s daily assignments was the major issue causing the significant cost overruns and delays in scheduled delivery times. Just like in manufacturing facilities, broken planning processes resulted in actual work windows being shortened from weeks to days, frustrating everyone involved.

The Challenge

CBS was challenged to address the progressing issues. Our initial investigation of the shipyard’s problems uncovered a root cause and subsequent issues, including:

- A master schedule that did not include alignment through all stakeholders

- Stakeholders not being present to turn the master schedule into a make-work plan

- Work activity constraints not being addressed in a time frame to ensure success

- Poor communication between project managers, schedulers and trades

- Subjective progressing methods differing between departments

- Limited activity planning and activity breakdown into work assignments

The Approach

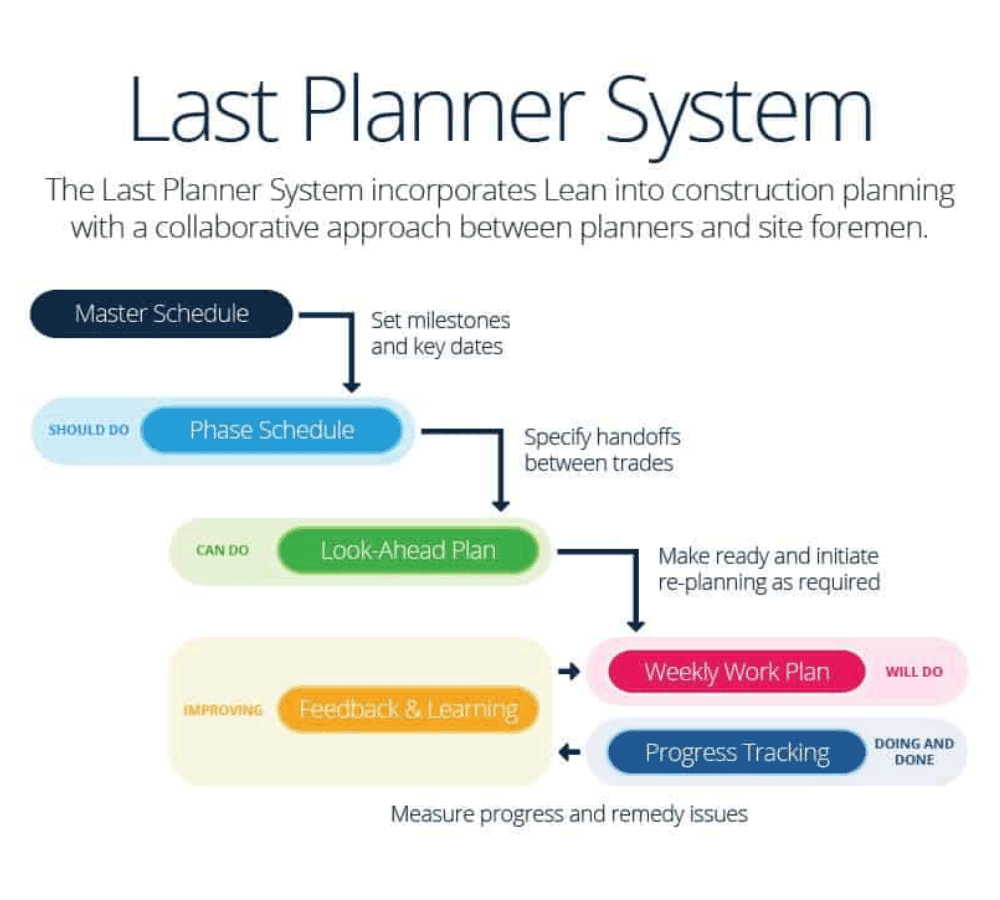

Ship walks, interviews, performance reviews and data analysis were used to pinpoint the progressing issues and their root causes. We would fix the progressing issues through schedule execution alignment and work assignment breakdown. Utilizing Last Planner Methodology for large construction sites would be the key, due to the changing nature of repair work with critical trades and sub alignment. Last Planner is an operational planning and control system created to address uncertainty and design an executable plan aligned to customer scheduling requirements. Implementation with a cross-functional team included these activities:

- Master Schedule: provide the milestones, key events and key dates.

- Phase Schedule: Monthly Milestone Planning – identify the next upcoming milestone based on master schedule key events and work aligned to the planned execution pace. Visual Management poster paper with calendar weeks aligned to key events are across the top. Trades and key subs are listed down the far left. When a trade supervisor places an activity in a given week, visibility is provided to everyone, with interference and constraints aligned or targeted for resolution.

- Look-Ahead Plan: 4-Week Look-Ahead Schedule – includes task breakdown where people (skills, trades and subcontractors), materials, tools & equipment, information and interferences are defined. Execution constraints are identified with an assigned owner and due date. Milestone Planning feeds into the weekly Look-Ahead Schedule as work activities are broken down into task assignments.

- Weekly Work Plan: Weekly Plan by the day – from the Look-Ahead Schedule, the executable (clear path) tasks are planned. Alignment is obtained from trades, subs and ships force.

- Feedback & Learning: Daily Metrics are reviewed, with any issues requiring recovery plans triggering root cause corrective actions.

Detailed preparation was the critical step for turning status update meetings into effective alignment sessions. As work items and activities were clearly defined and standard work was documented, the culture changed, team members started to communicate more effectively, work started to be better planned and executed on time and the cost overruns were reduced.

The final phase of the implementation was to transfer the process to someone internally to make sure the improvements were sustained. CBS deployed its Build It, Run It and Transfer It methodology to ensure that the team was able to continue to make improvements going forward. This approach worked seamlessly, as the hand-off person is still using and improving the practices deployed.

Results

Within a few weeks of engagement, significant results became evident:

| JOP | Ending | Improvement | |

| Percent Planned Complete: | 8% | 22% | 175% |

| Clear Path Percent: | 45% | 74% | 64% |

The new methodology has been adopted as a standard for all the client’s ship repairs sites.

Conclusion

The executive engaged CBS because of our reputation for taking each assignment beyond face value and digging deeper to address root causes with creative implementation of tools that could be used on site and across multiple shipyards. For this job, CBS leveraged our construction and ship building experience to apply the Last Planner Methodology to the complexities of shipyard repair. We further utilized visual-management systems to overcome constraints and design processes that were aligned to all stakeholders. With the transfer process, this new methodology has become the new standard for all their repair shipyards.

Case Studies:

Join our community.

Sign up now to receive future news.